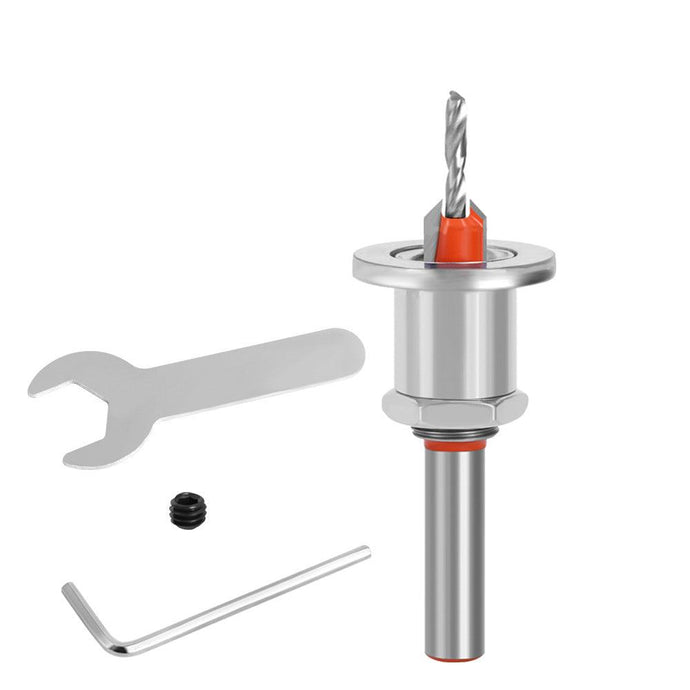

Metal Countersink Bit

The Precision Edge: Unlocking the Power of Metal Countersink Bits

In the realm of metalworking and woodworking, achieving a perfect finish is paramount. One tool that plays a crucial role in this process is the metal countersink bit. Designed to create a conical hole that allows screws or bolts to sit flush with the surface, these bits are essential for both aesthetic appeal and functional integrity. Understanding the design, applications, and benefits of metal countersink bits can greatly enhance the quality of your projects.

Metal countersink bits are specifically engineered to cut a conical shape into the surface of a material, typically metal or wood. This shape allows for the smooth insertion of fasteners, ensuring they sit flush or slightly below the surface. By creating a recessed area for the screw head, countersink bits help prevent snagging and provide a more polished look, which is particularly important in visible areas or for furniture assembly. Their versatility makes them a go-to tool for various applications, from automotive repair to cabinetry.

One of the primary advantages of using metal countersink bits is their ability to prevent damage to the surface of the workpiece. When screws or bolts are driven into a material without a countersink, the surrounding material can be displaced, leading to cracks, splinters, or an uneven finish. By using a countersink bit, the material is evenly removed, allowing for a smooth and consistent surface. This is especially important when working with softer materials, where a standard drill bit could easily cause unwanted damage.

The construction of metal countersink bits plays a significant role in their effectiveness. Most are made from high-speed steel (HSS) or carbide, which ensures durability and resistance to wear. HSS bits are particularly favored for their balance of toughness and sharpness, allowing for clean cuts even in tougher materials. Carbide-tipped countersink bits offer even greater longevity and are ideal for high-production environments where consistent performance is crucial. The choice of material will depend on the specific application and the frequency of use, but both options provide excellent results when used appropriately.

Selecting the right countersink bit involves considering the size and angle of the conical hole needed. Countersink bits typically come in various sizes and angles, with the most common being 82, 90, and 100 degrees. The angle you choose should match the angle of the screw head being used; for instance, a standard flat-head screw generally requires a 90-degree countersink. Additionally, ensuring that the diameter of the bit aligns with the screw size is crucial for achieving a perfect fit. When in doubt, it's always a good practice to refer to the manufacturer's specifications or guidelines.

Using metal countersink bits requires a degree of skill and precision. To achieve the best results, it's essential to start with a pilot hole that matches the screw diameter. This pilot hole guides the countersink bit and helps prevent wandering, ensuring that the final result is accurate. When drilling, maintain a steady hand and moderate pressure to avoid overexerting the bit, which can lead to uneven cuts or damage to the workpiece. Keeping the bit cool during operation is also important; using cutting oil can reduce friction and prolong the life of the bit.

In addition to their traditional use in metal and wood, countersink bits have found applications in composite materials and plastics. As manufacturing processes evolve, the need for precision in these materials has become increasingly important. Using countersink bits allows for clean, flush installations of fasteners, which is essential for both structural integrity and appearance. As industries continue to innovate, understanding the versatility of these bits becomes crucial for staying ahead in the market.

The benefits of using metal countersink bits extend beyond aesthetics and surface protection. When screws sit flush with the material, they reduce the risk of snagging and provide a safer environment, especially in high-traffic areas. In cabinetry and furniture assembly, countersinking screws also contributes to the strength of the joint, helping to distribute stress evenly across the material. This not only enhances durability but also reduces the likelihood of future repairs or replacements, making countersink bits a wise investment.

Maintenance and care of metal countersink bits are essential for ensuring their longevity and performance. After use, it's advisable to clean the bits thoroughly to remove any debris or metal shavings that may have accumulated. Storing them in a dry, organized manner will help prevent damage and keep them sharp for future projects. Regularly inspecting the bits for wear and tear can help identify when they need to be replaced, ensuring that you always have the tools necessary for achieving the best results.

Ultimately, metal countersink bits are invaluable tools that combine precision with practicality. They enhance both the functionality and appearance of fastened joints, making them essential for a wide range of applications. By understanding their design, selecting the appropriate type, and employing proper techniques, anyone from DIY enthusiasts to seasoned professionals can unlock the full potential of metal countersink bits, achieving flawless results in their projects. In the world of craftsmanship, where detail matters, these bits are undoubtedly a game changer, providing that ultimate edge in quality and performance.